USB is the successor to RS 232, which was implemented in

many different ways, causing untold confusion and frustration with the

standard. In contrast, the USB is a huge improvement as an industrial

standard, which was first developed in about 1990.

The standard defines

cables, connectors and communication protocols used in a bus for connection,

negation and power supply between computers and electronic devices. USB was initially

designed to standardise the connection of computer peripherals including

keyboards, pointing devices, digital cameras, printers, portable media players,

disk drives and network adapters. It has since become commonplace on other

devices, such as smart phones, PDAs and video game consoles, effectively replacing

a variety of earlier interfaces including RS 232 and parallel transmission, as

well as separate power chargers for portable devices.

As the name says, USB is a serial protocol which means data

is transferred bit by bit in an isochronous fashion.

Overview

In

general, there are three basic formats of USB connectors: the default or standard format intended for desktop or

portable equipment (for example, on USB flash

drives), the mini intended for mobile equipment (now deprecated except the

Mini-B, which is used on many cameras), and the thinner micro size, for low-profile mobile equipment (most modern mobile

phones).

There are

also five modes of USB data transfer, in order of increasing bandwidth:

·

Low Speed (from 1.0)

·

Full Speed (from 1.0)

·

High Speed (from 2.0)

·

SuperSpeed (from 3.0)

·

SuperSpeed+ (from 3.1)

These

modes have differing hardware and cabling requirements. USB devices have some

choice of implemented modes, and USB version is not a reliable statement of

implemented modes. Modes are identified

by their names and icons, and the specifications suggests that plugs and

receptacles be colour-coded (SuperSpeed is identified by blue).

Unlike

other data buses (e.g., Ethernet, HDMI), USB connections are directed, with

both upstream and downstream ports emanating from a single host. This applies

to electrical power, with only downstream facing ports providing power. This

topology was chosen to easily prevent electrical overloads and damaged

equipment. Thus, USB cables have different ends: A and B, with different

physical connectors for each.

Therefore,

in general, each different format requires four different connectors: a plug

and receptacle for each of the A and B ends. USB cables have the plugs, and the

corresponding receptacles are on the computers or electronic devices. In common

practice, the A end is usually the standard format, and the B side varies over

standard, mini, and micro.

(Remember that when referring to receptacles and plugs, they

are often called females and males respectively.)

The mini

and micro formats also provide for USB

On-The-Go with a hermaphroditic AB receptacle, which accepts either an A or a B

plug. On-the-Go allows USB between peers without discarding the directed

topology by choosing the host at connection time; it also allows one receptacle

to perform double duty in space-constrained applications.

There are

cables with A plugs on both ends, which may be valid if the cable includes, for

example, a USB host-to-host transfer device with 2 ports, but they could also

be non-standard and erroneous and should be used carefully.

The micro

format is the most durable from the point of view of designed insertion

lifetime. The standard and mini connectors have a design lifetime of 1,500

insertion-removal cycles, while the improved Mini-B connectors increased this

to 5,000. The micro connectors were designed with frequent charging of portable

devices in mind, so they have a design life of 10,000 cycles and also place the

flexible contacts, which wear out sooner, on the easily replaced cable, while

the more durable rigid contacts are located in the receptacles. Likewise, the

springy component of the retention mechanism, parts that provide required

gripping force, were also moved into plugs on the cable side.

USB Standard - Development

Now

let's have a look at the development of the USB standard. It started in January

1996 with USB One, which defined data transfer

rates of 1.5Mbit/s Low Speed and 12 Mbit/s Full

Speed. The USB Version 2 was released in April 2000 and ratified by

the end of 2001. It introduced a higher data

transfer rate, with the resulting specification achieving 480 Mbit/s, an

increase of 40 times over the original USB 1.1 specification.

The USB 3.0 specification was published on 12 November 2008. Its

main goals were to increase the data transfer rate (up to 5 Gbit/s), decrease

power consumption, increase power output, and be backward compatible

with USB 2.0.

USB 3.0 included a new, higher speed bus

called SuperSpeed in parallel with the USB 2.0 bus. For this reason, the new

version is also called SuperSpeed. The first USB 3.0 equipped devices were

presented in January 2010.

As of 2008, approximately 6 billion USB ports and interfaces

were in the global marketplace, and about 2 billion were being sold each year.

Finally, the last version to take note of is the USB C connector

Or USB type C.

Developed at roughly the same time as the USB 3.1 specification,

but distinct from it, the USB Type-C Specification 1.0 was finalized in August

2014 and defined a new, small reversible-plug connector for USB devices.

The Type-C plug connects to both hosts and devices, replacing various Type-A

and Type-B connectors and cables with a standard meant to be future-proof,

similar to Apple Lightning and Thunderbolt.

The 24-pin double-sided connector provides four power-ground

pairs, two differential pairs for the USB 2.0 data bus (though only one

pair is implemented in a Type-C cable), four pairs for high-speed data bus, two

"sideband use" pins, and two configuration pins for cable orientation

detection, dedicated biphase mark code (BMC)

configuration data channel, and VCONN +5 V power for active

cables. Type-A and Type-B adaptors and cables are required for older

devices to plug into Type-C hosts. Adapters and cables with a Type-C receptacle

are not allowed.

Connectors

Having

covered the different releases of USB let's have a look at the different

connectors used.

Below

is a picture of the different connectors. As you can see, up to release three

they all have four pins except the mini and micro, which have five pins but the

fifth pin is not wired and is used for ID purposes.

The connectors are designed so they cannot be exchanged or plugged in

the wrong way to avoid shorts and damage to the equipment. What might be worth

mentioning is the Power-use topology. (For

more information on topology in networking, visit the website in the

recommended reading below.)

The

standard connectors were deliberately intended to enforce the directed topology of a USB

network: type-A receptacles on host devices that supply power and type-B

receptacles on target devices that draw power. This prevents users from

accidentally connecting two USB power supplies to each other, which could lead

to short

circuits and dangerously high currents, circuit failures, or even fire.

USB does not support cyclic networks and the standard connectors from

incompatible USB devices are incompatible themselves.

However,

some of this directed topology is lost with the advent of multi-purpose USB

connections (such as USB

On-The-Go in smartphones, and USB-powered Wi-Fi routers), which require A-to-A,

B-to-B, and sometimes Y/splitter cables. If anybody is interested in the USB on

the go connectors please let me know and I will provide more information.

Durability

The standard connectors

were designed to be robust. Because USB is hot-pluggable, the

connectors would be used more frequently, and perhaps with less care, than

other connectors. Many previous connector designs were fragile, specifying

embedded component pins or other delicate parts that were vulnerable to bending

or breaking. The electrical contacts in a USB connector are protected by an

adjacent plastic tongue, and the entire connecting assembly is usually

protected by an enclosing metal sheath.

The connector

construction always ensures that the external sheath on the plug makes contact

with its counterpart in the receptacle before any of the four connectors within

make electrical contact. The external metallic sheath is typically connected to

system ground, thus dissipating damaging static charges. This enclosure design

also provides a degree of protection from electromagnetic interference to the

USB signal while it travels through the mated connector pair (the only location

when the otherwise twisted

data pair travels in parallel). In addition, because of the required

sizes of the power and common connections, they are made after the system

ground but before the data connections. This type of staged make-break timing

allows for electrically safe hot-swapping.

Features intended to

accomplish extended life, include a locking device, while the leaf-spring was

moved from the jack to the plug, so that the most-stressed part is on the cable

side of the connection. This change was made so that the connector on the less

expensive cable would bear the most wear instead of the more expensive Micro-USB

device. However, the idea that these changes did in fact make the connector

more durable in real world use has been widely disputed, with many contending

that they are in fact, much less durable.

Colour-coded Connectors

Below are images of the different colour-coded USB

connectors.

Now let's have a look at the cabling used in USB. USB One

and Two used one twisted pair for the data transfer and two wires for the

power. Wires are used in different thickness.

Generally wire thickness is expressed in American Wire Gauge

the acronym being AWG. The thicker the cable the better the transmission

capabilities and the power which can be transmitted. However, to make the cable

flexible and thin, the data pair generally uses AWG 26 or 28 and the power 24

or 26. The higher the AWG number, the thinner the cable. Worth mentioning here

is also that solid copper wire gives you better transmission capabilities, but

since it breaks easily, for short cables stranded wire is chosen. Incidentally

superspeed cables will always use 26 AWG.

The maximum length of USB cables is 5 m, if the client needs

a longer cable you need a booster.

The Construction of a Good Cable

First off, although most USB cables may look alike externally, the internal wiring may be very different. For this reason, you may find that certain USB cables such as phone chargers are unable to charge your phone, or charge more slowly or faster than the original cable you purchased with your phone. The same principle applies to other uses of USB cables – not all are created equal.For the purposes of this article, we’re going to explore the concept of mobile phone USB cables, the majority of which use a USB 2.0 connector. There are five wires inside the USB 1 and USB 2 cables, and there are more inside USB 3.0 cable, which we won’t look at today.

The five

wires are:

·2 x 28

AWG data lines

·2 x 20-28

AWG power conductors

·1 x drain

wire

These

five wires are connected to the five pins in your micro-USB connector.

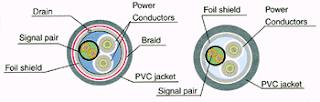

In fact, there are two kinds of USB cable: fully-rated and sub-channel. The main difference between them is that fully-rated cable can be used for typical peripherals operating at a rate of 480 Mbps (high speed) signalling, while the sub-channel one operates at a rate of 1.5 Mbps (standard speed) signalling. The construction inside the cable fully-rated and sub-channel cable is different.

In fact, there are two kinds of USB cable: fully-rated and sub-channel. The main difference between them is that fully-rated cable can be used for typical peripherals operating at a rate of 480 Mbps (high speed) signalling, while the sub-channel one operates at a rate of 1.5 Mbps (standard speed) signalling. The construction inside the cable fully-rated and sub-channel cable is different.

Like most shielded cables USB cables use an aluminium and a mylar foil, resulting in 100% shielding against interference. Some USB cables use a metal braid, but this is purely for physical protection.

Testing USB Cables

For data, the easiest is to just connect a device to a PC to

see whether it works. For charging cables, you can download an app called

"Ampere".

However, for more sophisticated and quantity testing, Tektronix

and Fluke sell specialised testing equipment.

The test equipment officially supported by the USB forum is

the Sigtest tool. You can order this tool and get all the information at www.USB.org.

In Summary

A good cable is defined by the AWG and the shielding used.

For increased strength of the link between the connector and

the cable, Teflon can really help the durability of the cable.

To purchase 100% quality tested, custom cables, visit my

website at http://www.customcables.co.za

Recommended Reading

http://voyager8.blogspot.co.za/2013/04/how-to-choose-good-usb-data-and.html

https://www.studytonight.com/computer-networks/network-topology-types

No comments:

Post a Comment